Deburring the micropores of the titanium plate is a special process, which needs to be selected according to the specific size, shape and requirements of the micropores of the titanium plate. The following are some optional microporous deburring processes for titanium plates:

Pickling: Pickling is one of the common methods for micropore deburring of titanium plates. This method can effectively remove impurities and burrs on the metal surface by soaking the titanium plate in concentrated acid. Before pickling, it is necessary to choose different acid solutions and treatment time according to the specific situation. After handling, it can be rinsed thoroughly with water and dried.

Plasma Etching: Plasma Etching is a physical method that removes burrs by removing tiny particles from the microporous surface of titanium plates. This method will not cause damage to the metal surface, so it is very suitable for processing the micropores of titanium plates with small apertures and high precision requirements. Plasma erosion usually needs to be combined with high-energy ion bombardment to achieve better results.

Laser processing: Laser processing is a non-contact processing method that can ensure the accuracy and smoothness of the surface shape of the micropores of the titanium plate. By laser irradiation, tiny burrs can be quickly removed to form a smooth surface.

Machining: Through the machining process, the micro-holes of the titanium plate can be deburred with high precision and high processing efficiency. It mainly includes drilling, stretching, milling, etc. Drilling is a commonly used processing method. By controlling the size and speed of the drill bit, it can achieve the purpose of deburring with high precision and smooth surface.

The above are several commonly used titanium plate micropore deburring processes, and the specific selection should be made according to the specific conditions and requirements of the titanium plate micropores.

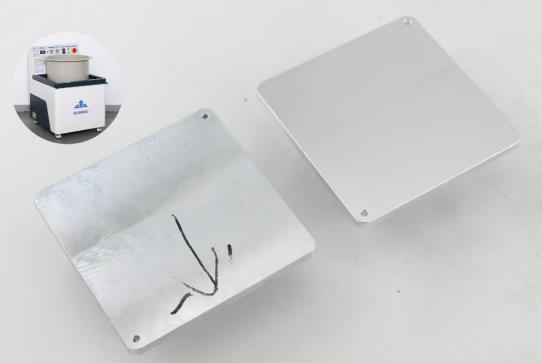

The magnetic grinding machine does not affect the accuracy of the workpiece

Titanium plate refers to the plate made of pure titanium or titanium alloy. Because titanium has the characteristics of low density, high strength, good high temperature oxidation resistance and chemical inertness, titanium plate is widely used in the following fields:

Aerospace field: Titanium plates are widely used in the aerospace field to manufacture aero-engines, aircraft intakes, ship axles and other components. Its light weight and high strength characteristics can help reduce weight and improve strength.

Medical industry: Titanium plates are also widely used in the medical industry, such as artificial joints, dental implants, surgical instruments, etc. Because titanium has good biocompatibility, it can avoid allergic or rejection reactions to the human body.

Chemical industry: Because of its good corrosion resistance, titanium plates are widely used in the chemical industry to manufacture high-pressure reactors, lining pipes and other equipment.

Magnetic grinding and polishing machine energy saving and environmental protection

Food processing industry: Due to its non-toxic, odorless and non-rusting properties, titanium plates can be used in the food processing industry to manufacture food equipment, such as food mixers, dessert dispensers, milk heaters, etc.

Automobile manufacturing: Due to its light weight and high strength, titanium plates are used in the automobile manufacturing industry, such as manufacturing automobile wheels, exhaust pipes and other components, reducing the weight of the body and improving fuel economy.

Titanium plates have a wide range of uses and have been widely used in high-tech fields. With the continuous development of science and technology, the application fields of titanium plates will become more and more extensive.

You must be logged in to post a comment.