With the continuous improvement of China’s industrial level, aluminum alloy tubes are widely used in aviation, automotive, electronics and other fields. Polishing as an important part of the aluminum alloy tube processing process, the surface quality of the tube has a significant impact. In this paper, we will have an in-depth discussion on aluminum alloy tube polishing technology, analyze the characteristics and scope of application of different polishing methods, in order to provide reference for the development of China’s aluminum alloy tube polishing technology.

First, the importance of aluminum polishing

Aluminum alloy tube has the advantages of light weight, high strength, corrosion resistance, etc. However, in the process of processing, the surface of the tube is prone to produce oxide film, scratches and other defects. Polishing can effectively remove these defects, improve the surface finish and aesthetics of the tube surface, and extend the service life. In addition, polishing can also improve the welding performance, painting performance and assembly performance of aluminum alloy tube, reduce product failure rate.

Second, aluminum polishing methods and characteristics

- Manual polishing: manual polishing mainly uses sandpaper, polishing paste and other tools to grind and polish the surface of aluminum alloy tube. The method is simple, low cost, but low efficiency, and the polishing quality is affected by the operator’s skill level.

- mechanical polishing: mechanical polishing using polishing machine, polishing wheel and other equipment, aluminum alloy tube for efficient and uniform polishing. The method of polishing quality is stable, high efficiency, but the equipment investment is larger, higher cost.

- chemical polishing: chemical polishing is to remove the oxide film and dirt on the surface of aluminum alloy tube through chemical reaction to achieve polishing effect. The method is suitable for mass production, low cost, but the environmental pollution is larger, the operation requirements are higher.

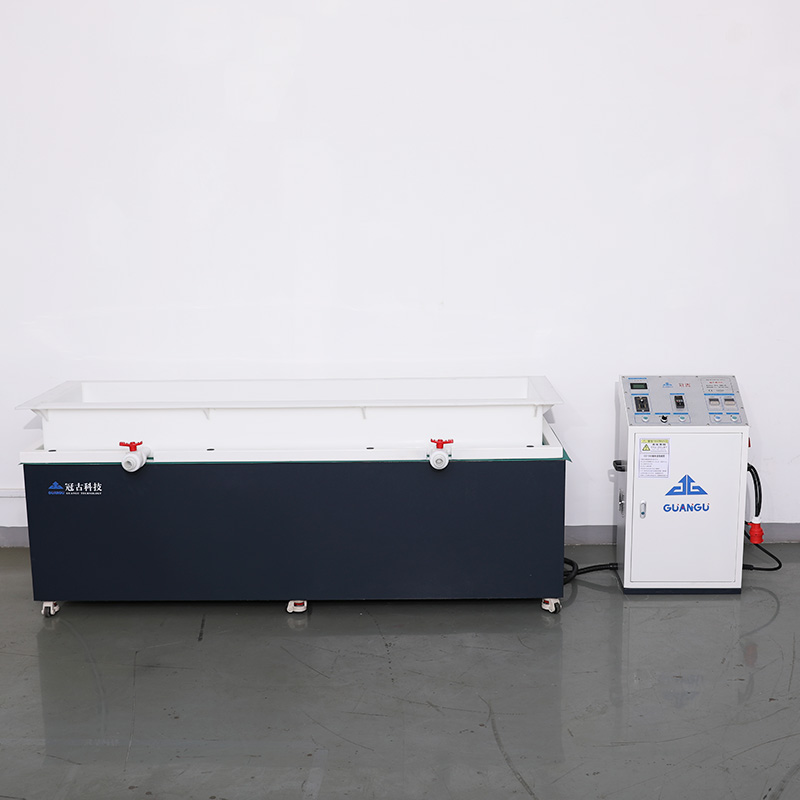

- Electrolytic polishing: Electrolytic polishing uses the electrochemical reaction in the electrolyte solution to polish the surface of aluminum alloy tube. The method of polishing high quality, fast efficiency, but the equipment cost is higher, the operation is complicated.

- laser polishing: laser polishing using high-energy laser beam on the surface of aluminum alloy tube irradiation, so that its evaporation, melting, to achieve the polishing effect. The method of polishing quality is very high, suitable for high-precision requirements occasions, but the equipment cost is very high, the operation is complicated.

Third, the development trend of aluminum alloy tube polishing

- Green environmental protection: with the strengthening of China’s environmental awareness, chemical polishing and other methods of environmental pollution will gradually be eliminated, replaced by environmentally friendly polishing technology.

- energy efficient: in order to reduce production costs and improve production efficiency, the future of aluminum alloy tube polishing technology will be energy efficient direction.

- Intelligent: with the development of artificial intelligence, robotics, aluminum alloy tube polishing will be automated, intelligent, improve polishing quality.

- Multi-technology fusion: in order to meet the polishing needs of different occasions, the future aluminum alloy tube polishing technology will realize the fusion of various technologies, give full play to their respective advantages and improve the polishing effect.

Summary: Aluminum alloy tube polishing technology has important application value in aviation, automobile, electronics and other fields. With the continuous improvement of China’s industrial level, aluminum alloy tube polishing technology will continue to progress, providing strong support for China’s aluminum alloy tube processing industry.

You must be logged in to post a comment.